Custom Fabrication

Fabrication capabilities that shape nuclear solutions

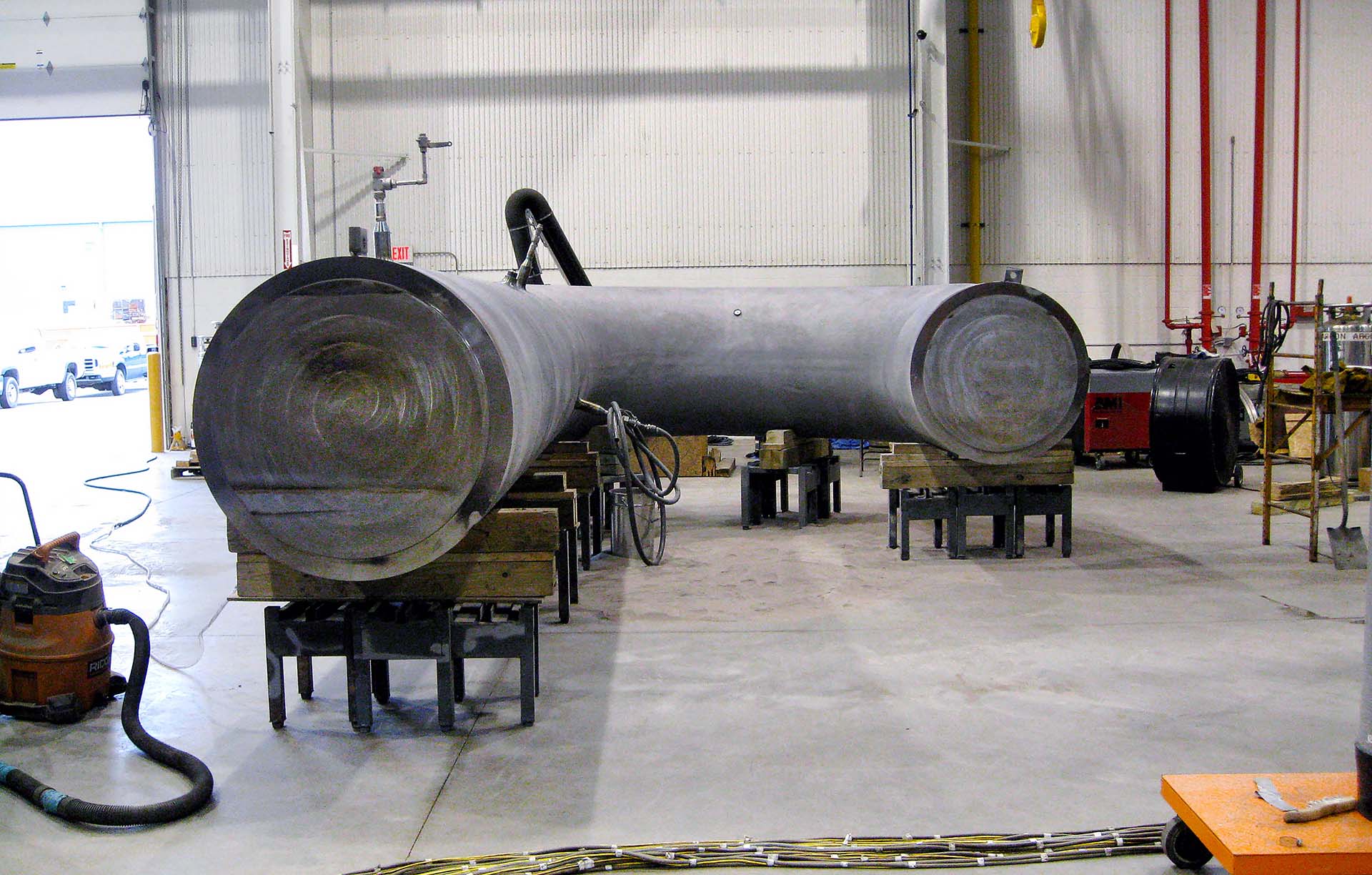

With our vast expertise in obsolescence solutions, new equipment manufacturing, welding, and precision machining, Energy Steel has the capabilities to custom fabricate a wide range of parts and components to solve complex challenges for nuclear facilities.

Materials We Fabricate

At Energy Steel, there’s no custom fabrication challenge we can’t handle. Since our founding in 1982, we’ve been dedicated to the success of the nuclear industry as a material supplier, and that includes the manufacturing of both new and obsolete parts that are critical to the global nuclear energy sector.

At our state-of-the-art manufacturing facility in Rochester Hills, Michigan, we have the capabilities to produce custom metal components, including:

P1

Carbon Manganese Steels

P3

1/2 Molybdenum or 1/2 Chromium, 1/2 Molybdenum

P8

Austenitic Stainless Steels

P42

Nickel, Copper – (Monel 500)

P10H

Duplex and Super Duplex Stainless Steel

P34

Copper Nickel

P6

Martensitic Stainless Steels

P5A

2 1/4 Chromium, 1 Molybdenum

P41

High Nickel Content

P43

Nickel, Chromium, Iron – (Inconel)

We have the ability to engineer and fabricate these components to suit a wide variety of new equipment builds, as well as solve obsolescence issues when parts and equipment are no longer manufactured.

Welding

Our capabilities—including staff expertise and state-of-the-art welding equipment—enable us to complete a wide range of fabrication, including welding. We’re experienced in gas metal arc welding (GMAW), flux cored arc welding (FCAW), gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and torch brazing (TB).

We are also experienced in corrosion-resistant overlay and wear-resistant overlays using a variety of alloys depending on the application, including stainless steel, Inconel, Stellite, and others using processes like GTAW, GMAW, and FCAW.

Welding Equipment We Use

- Weld Machine (9) Miller PipeWorx 400 Mig – Pulse, flux core welding, TIG and stick welding

- Welding Machine Calibration Miller LB-001 – Power load bank welder calibration machine. This portable unit can be used to test AC/DC welder outputs, and to demonstrate welding equipment to prospective customers. Has a maximum load testing of 750 Amperes @ 50 Volts.

- Welding Preheat & Heat Treat Pro Heat 35 Induction Heating Machines – Electromagnetically heats parts for preheat applications. Heating temperature up to 1450̊F.

- Hotfoil Heating Oven, 24” x 24” x 24”

- Heat Treating Oven 4

- Rod Oven Grieve HB 500, 38” x 26” x 50” – Heats up to 500°F

Machining

Our in-house machining capabilities add to our ability to provide custom fabrication services for our customers. Using state-of-the-art machining equipment and processes, our experienced team can build any part or component to quality standards with tight tolerances using a variety of methods.

Our manufacturing shop employs turning centers, lathes, CNC mills, drills, beveling, and several types of cutting to fabricate parts and components.

Learn more about our Machining Services.

Products We Fabricate

We solve obsolescence with our vast custom fabrication capabilities

Quick Response Services

When you don’t have time to wait.

When pressing needs arise, our Quick Response Team can help. As dedicated nuclear sourcing specialists, our Quick Response Team keeps your operations up and running. Our team handles projects from quote to shipment with unparalleled turnaround times to deliver what you need, when you need it.

Services:

- Engineered Solutions

- Emergency Needs

- ASME Sec III Material Supply

- Contingency Planning

- Outage Support

- OEM Products

- Code Reconciliation

Contact our Quick Response Team for:

- Pumps & Motors

- Valves

- Filters/Strainers

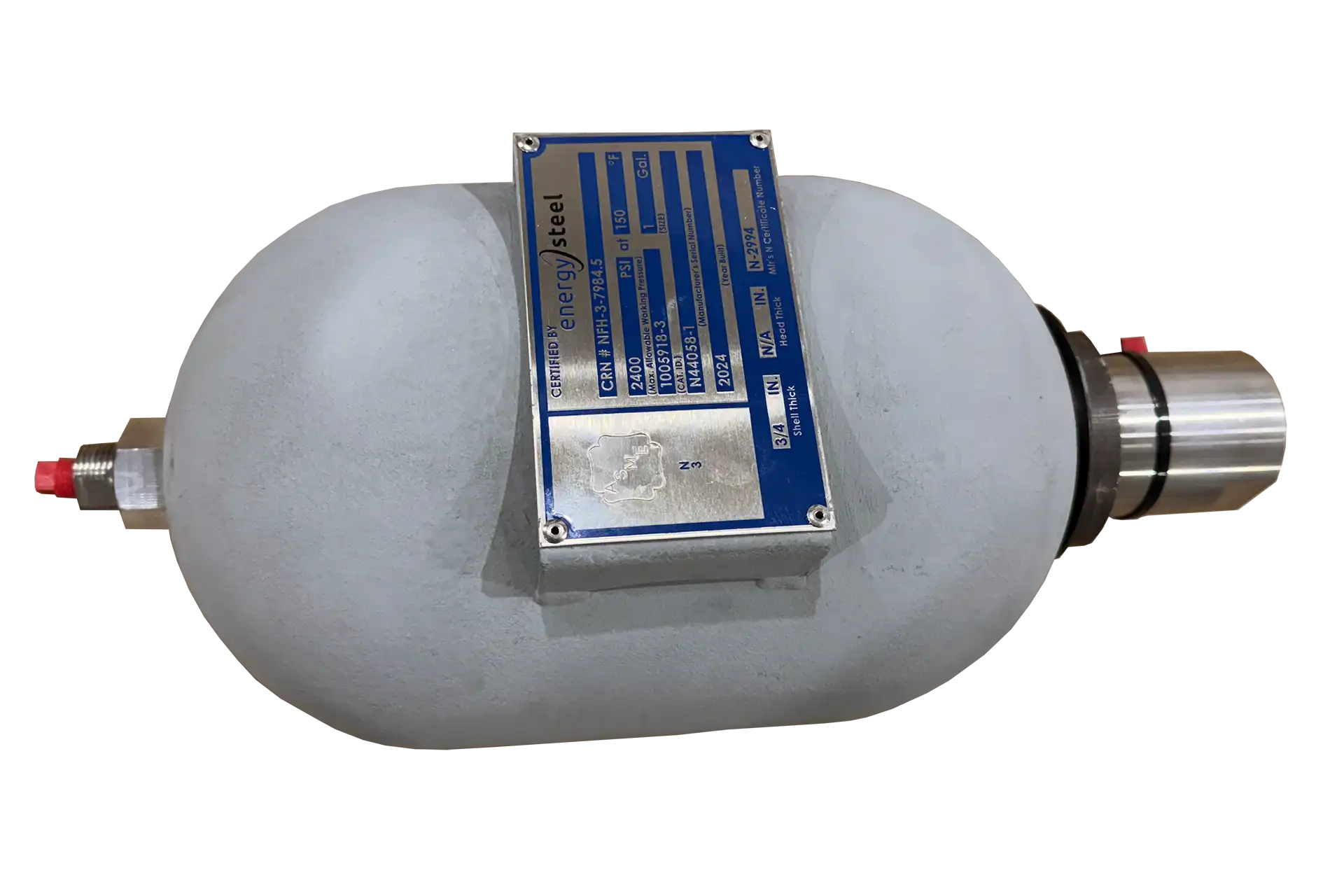

- Bladder Accumulators

- Machined Components

- Non-welded Assemblies

- Certified OEM Components

- Commercial-Grade Item Dedication

Call us today: (866) 261-3772 | Worldwide: (810) 538-4990

Want to Learn More About Our Custom Fabrication Capabilities?

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.