Engineering Services

Engineered to serve the needs of nuclear energy

At Energy Steel, our commitment to our customers is to provide a wide range of products and custom solutions to the nuclear energy industry, including custom-engineered parts and components that meet all necessary requirements. With quality at the forefront, we tackle complex problems and solve obsolescence issues to ensure continued nuclear operations.

Solving Obsolescence

Our innovative engineering team provides solutions for nuclear facilities that rely on obsolete safety-related components. Utilizing original OEM drawings and state-of-the-art engineering techniques, we can design and manufacture almost any part or component needed to keep your nuclear operations running. With more than 40 years of custom fabrication experience and in-house machining and welding capabilities, we can ensure precision, quality, and timely delivery.

Design Engineering

Our Design Engineering team is made up of both project managers and engineers who work together with our customers to provide turnkey solutions to the nuclear power industry’s manufactured parts and equipment needs. Our engineering and manufacturing capabilities enable us to create new solutions, solve obsolescence, and replace components that have reached the end of their defined useful life.

Once a contract is defined, our Engineering Team accepts responsibility for specification and code review, scheduling, design details, drawings, vendor contracts, customer approvals, and manufacturing plans.

For projects that require a new certified design, we coordinate with Registered Professional Engineers to create and finalize all the necessary documents. When a new design report is not required, our team utilizes internal resources and all available documents to support the project’s completion per the customer contract.

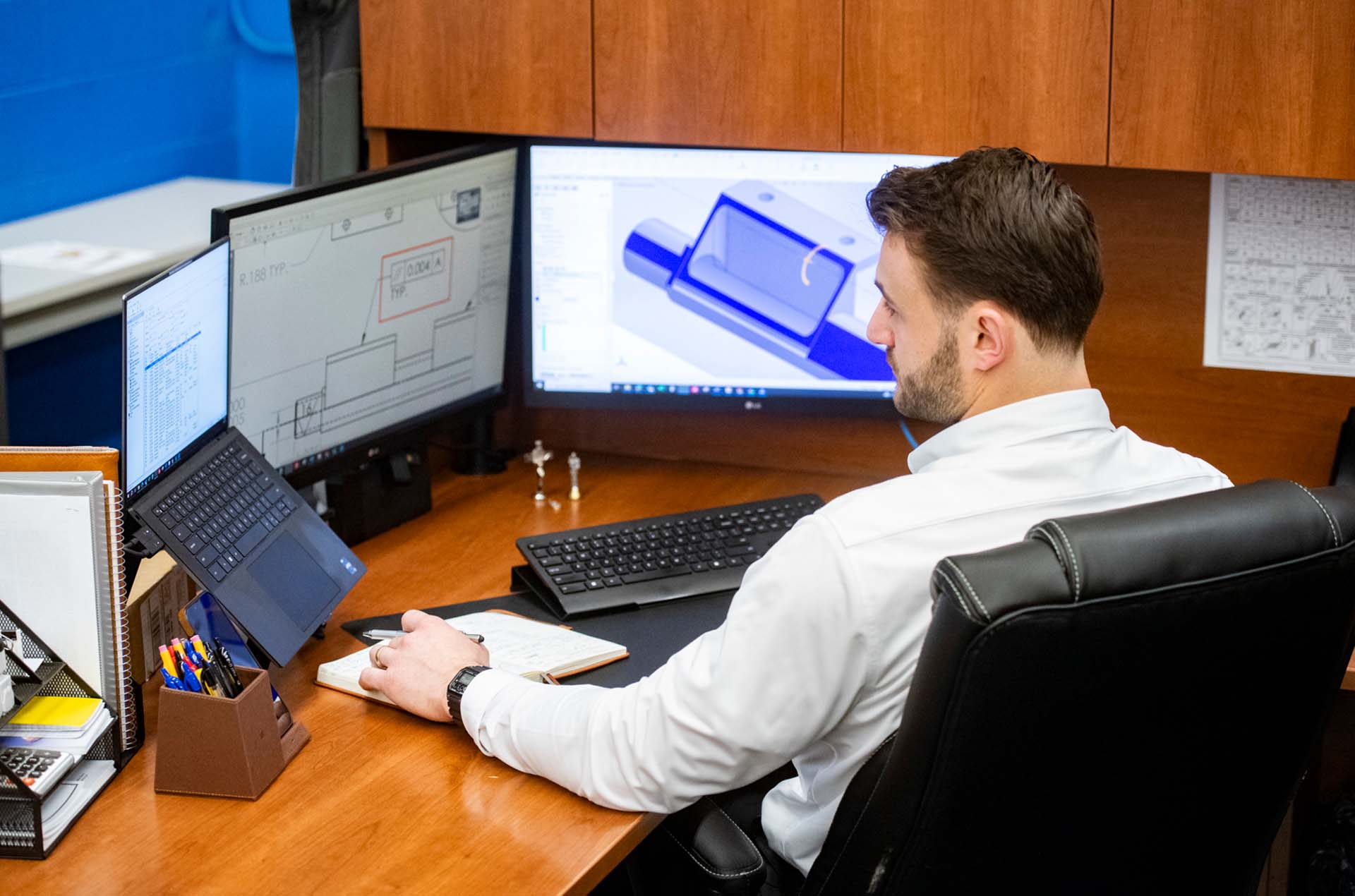

Engineering Design Software

We use many advanced technological advancements in engineering to carry out the design and analysis functions that are critical to quality and performance in nuclear operations. Our engineering team uses SolidWorks and Autodesk Inventor for 3D modeling and drawing creation and AutoCAD for drawing creation. We also employ COMPRESS software for ASME Section VIII code calculations, Mathcad for hand calculations, and Ansys for Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Seismic Analysis, and more.

Analysis

Our engineering team is dedicated to ensuring the safety, efficiency, and reliability of our products through rigorous analysis methods. We employ a range of techniques to assess and optimize our designs, including ASME Section VIII code calculations and ASME Section III design analysis to ensure compliance with industry standards and regulations. Computational Fluid Dynamics (CFD) enables us to simulate fluid flow and heat transfer within our systems, allowing for precise optimization of performance. Finite Element Analysis (FEA) allows us to model and analyze structural behavior under various conditions, ensuring structural integrity and reliability. Thermal calculations are used to evaluate heat distribution and manage thermal loads effectively. Additionally, our seismic analysis techniques ensure that our products can withstand seismic events and remain operational, even under extreme conditions. Through these comprehensive analyses, we deliver high-quality and reliable products to our customers.

Want to Learn More About Our Engineering Capabilities?

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.