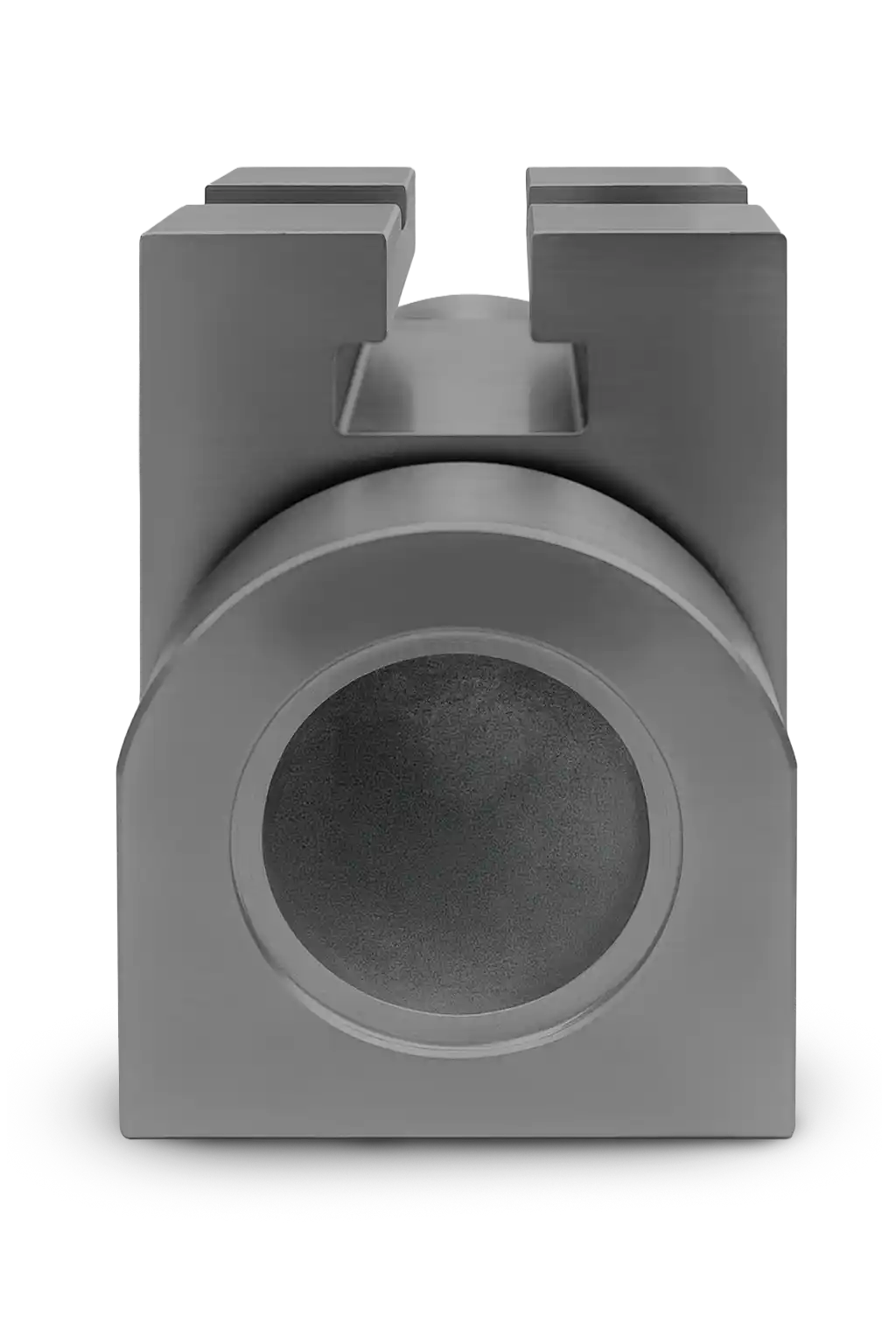

Ring-O Valves

Reliable subsea valves for challenging underwater pipelines

Cameron’s high-quality valves are trusted for reliable service in demanding environments. As an authorized teaming partner for Cameron brands, we manufacture RING-O brand ball valves, gate valves, check valves, and specialized small-bore valves that can meet the maintenance-free demands of subsea applications.

Product Overview

Engineered for excellence in deepwater applications, the comprehensive portfolio of RING-O Valves is designed to withstand the extreme pressures, temperatures, and conditions found in subsea production and pipeline transmission systems. Every RING-O valve is engineered for maintenance-free operation with a design life exceeding 25 years.

Ring-O Valves

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.