Hayward Tyler Pumps & Motors

Supporting nuclear energy with long-lasting, reliable pumping systems

Energy Steel partners with Hayward Tyler to supply a wide range of performance-critical pump and motor solutions for the nuclear industry. We manufacture Axial Mixed Flow Pumps, End Suction Pumps, Vertical Turbine Pumps, Double Suction Pumps, Canned Motor Pumps, and Wet Stator Motor Pumps—all engineered to fit customer requirements and deliver reliable and robust pumping solutions for nuclear applications.

Axial Mixed Flow Pumps

Product Overview

The MT/MN/BN series of Vertical Axial & Mixed Flow Pumps from Hayward Tyler are engineered for applications requiring large flow capacities at relatively low heads, or for situations where suction lifts exceed the capabilities of horizontal pumps. With multiple hydraulic designs available, these pumps can be customized to deliver varying capacity curve characteristics from steep to flat, making them highly adaptable to specific system requirements.

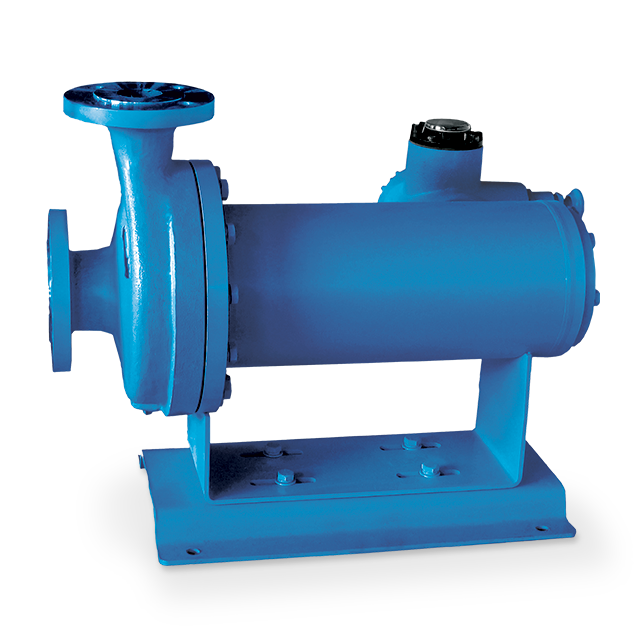

End Suction Pumps

Product Overview

The Hayward Tyler N3 is a vertically split, single-stage End Suction Pump specifically engineered for nuclear auxiliary and radwaste systems. Featuring a back pull-out design with flexible mounting options and a robust cantilever shaft/bearing arrangement, the N3 series is built to deliver exceptional reliability in demanding nuclear applications while ensuring low stress, minimal deflection, and extended bearing life.

Vertical Turbine Pumps

Product Overview

Hayward Tyler’s VS/VSC Vertical Turbine Pumps are engineered for applications requiring low NPSH (Net Positive Suction Head), medium head, and medium capacity installations. Specifically designed for the nuclear industry, these versatile pumps feature three different impeller types, each offering unique head-capacity curves ranging from steep to flat to meet diverse system requirements. With decades of operating experience, these pumps deliver reliable performance in both safety-related and non-safety related applications.

Double Suction Pumps

Product Overview

Hayward Tyler’s D/KSMK Series Double Suction Pumps are robust, high-capacity pumps designed with a horizontally or radially split configuration. These pumps are engineered specifically for critical applications in nuclear power facilities where reliability and safety are paramount. Their rugged design makes them particularly well-suited for hazardous, safeguard-operating conditions that require high flow rates at lower heads.

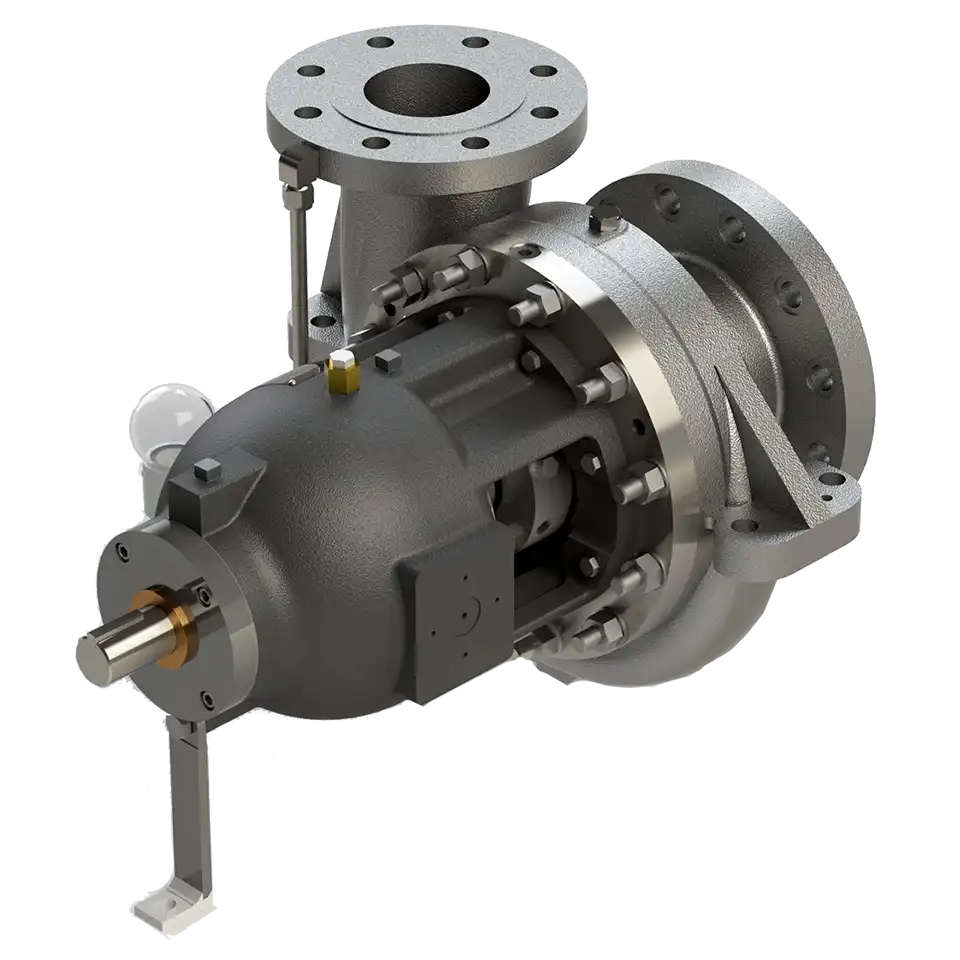

Canned Motor Pumps

Product Overview

Hayward Tyler’s Canned Motor Pumps are an innovative solution for nuclear applications where reliability and safety are paramount. These specialized pumps combine the pump and motor on a common shaft, all enclosed within a pressure boundary. By eliminating mechanical seals, they remove the risk of process fluid leaks.

We supply a wide range of Canned Motor Pumps: Engineered Canned Motor Pumps (CMP) and Retrofits (CMR), Internal Pressurized Circulation Pumps (HNP), Small Circulation Canned Motor Pumps (HX), Hollow Shaft Pumps (HV), High Capacity Pumps (HP/HT/HN), High Melting Point Pumps (HR), High Pressure, High Temperature Pumps (HTM), High Temperature Pumps Without Cooling Water (HV-X), High Temperature Pumps (HT), High Temperature High Melting Point Pumps (HR-Y), Multi-Stage Pumps (HP-M/HN-N/ HT-M/HW-M, HP-T), Reverse Circulation Pumps (HN), Self-Priming Pumps (HZ), Slurry Handling Pumps (HS), Slurry Handling Pumps with Gas Geal (HJ HG), Standard Pumps (HP), and Vertical Reverse Circulation Pumps (HW).

Wet Stator Unit (BCPs)

Product Overview

Hayward Tyler’s Wet Stator Unit Pumps, or Boiler Water Circulating Pumps, are advanced vertical pumps featuring an integrated wet wound motor design. These specialized units are engineered with matched pump and motor internal pressure ratings, eliminating the need for dynamic mechanical seals. This makes them particularly well-suited for high inlet pressure and temperature applications in nuclear facilities.

Hayward Tyler Pumps & Motors

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.