Basco/Whitlock Heat Exchangers

Low-cost, high-efficiency heat exchangers for reliable fluid heat transfer

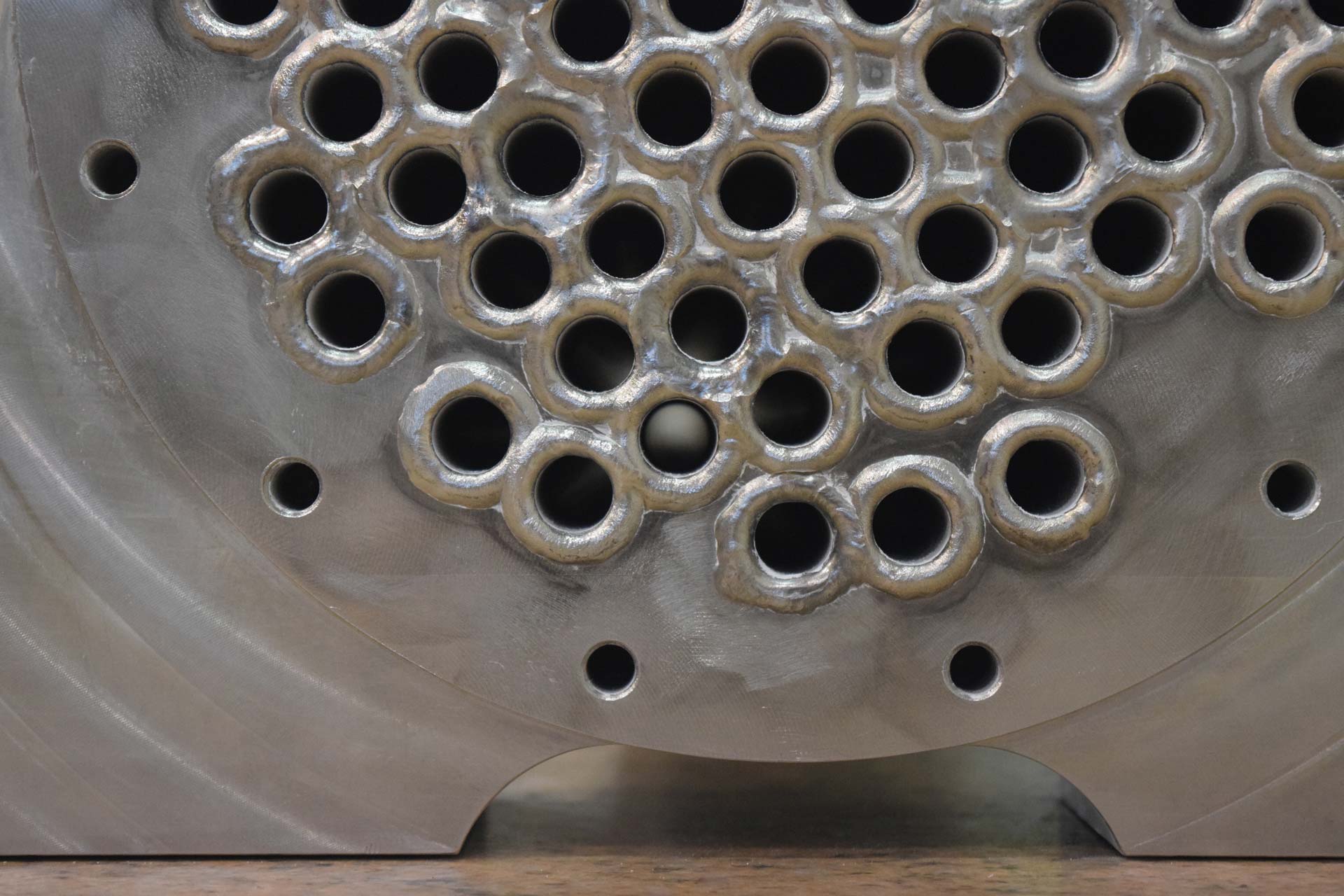

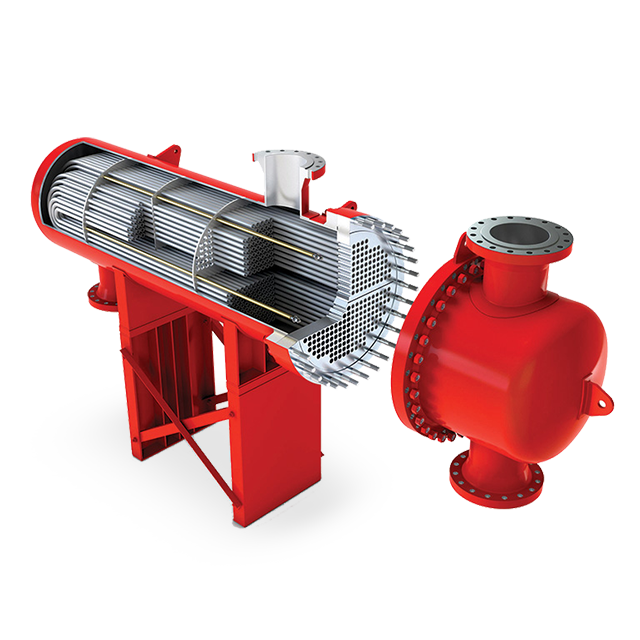

We are an authorized manufacturer of API Heat Transfer brands Basco® and Whitlock® Heat Exchangers. Available in shell and tube and hub-design styles, we provide custom-engineered solutions in a wide range of sizes, fulfilling almost every heat transfer need for nuclear facilities and a variety of other industries.

Product Overview

Basco/Whitlock heat exchangers represent the pinnacle of heat transfer technology, designed for exceptional performance in demanding applications. Available in three distinct series —R, ER, and SSH—Basco/Whitlock heat exchangers can be customized to meet virtually any industrial requirement. From standard TEMA designs to custom-engineered solutions, these products deliver superior thermal performance while maintaining the highest standards of quality and safety.

Product Series Details

- R Series: Standard removable bundle heat exchangers

- ER Series: 316 stainless steel exchangers for more demanding applications

- SSH Series: Premium heat exchangers with straight tube design

Photo Gallery

Basco/Whitlock Heat Exchangers

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.