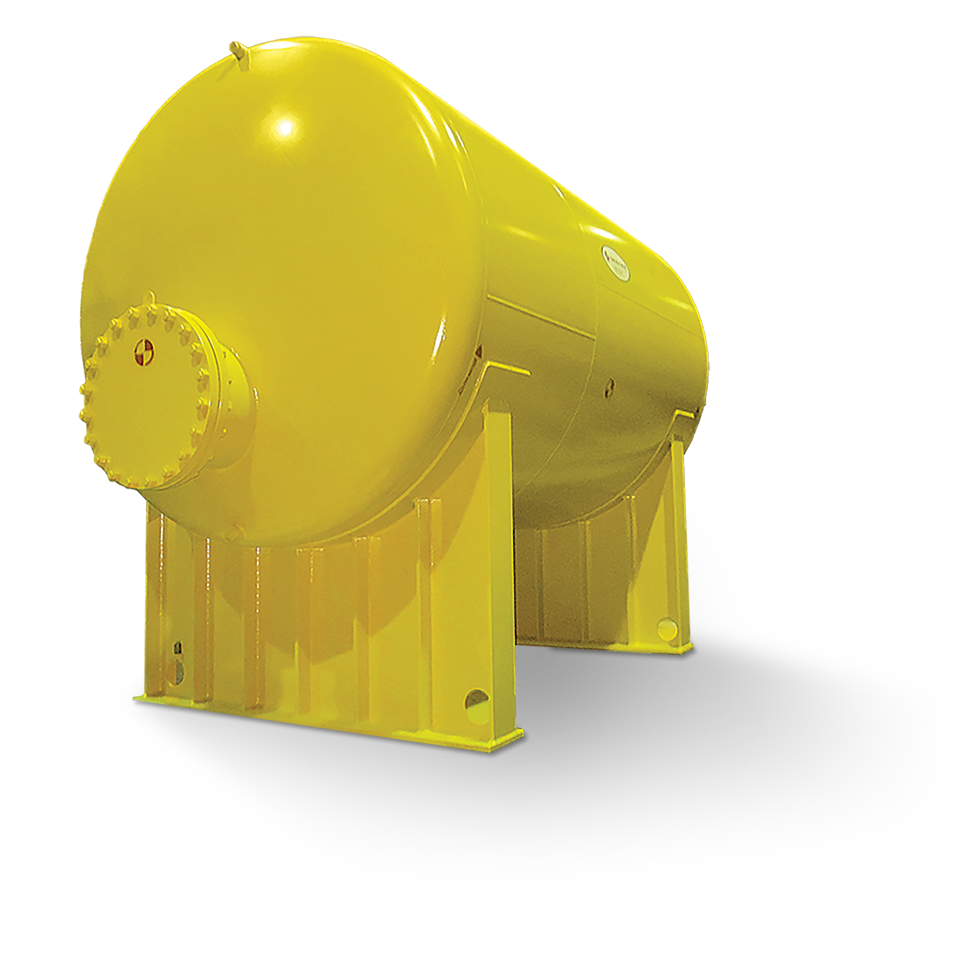

Tanks & Pressure Vessels

High-capacity stainless steel storage tanks for critical fuel and air applications

We design and fabricate custom storage tanks engineered to ASME Section III, Class 3 standards, including diesel fuel oil storage tanks and air receiver storage tanks. These large-capacity tanks provide reliable storage for nuclear power generation facilities, emergency backup systems, and industrial applications requiring the highest levels of quality assurance.

Product Overview

Our storage tanks are precision-engineered pressure vessels designed and fabricated to meet stringent ASME Section III, Class 3 requirements. We manufacture both Diesel Fuel Oil Storage Tanks and Air Receiver Storage Tanks for domestic commercial nuclear plants. Constructed from high-grade stainless steel, these custom tanks deliver exceptional durability, corrosion resistance, and long-term reliability for critical storage applications in nuclear and industrial facilities.

Photo Gallery

Tanks & Pressure Vessels

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.