Machining

Machining nuclear components with quality and precision

To maintain high quality standards and the fastest turnaround times, we provide machining services to fabricate components and build critical nuclear equipment with accuracy and precision. With our specialized equipment in our state-of-the-art facility, we’re able to produce high-quality products to exact specifications to serve the needs of nuclear facilities.

Machining Processes

At Energy Steel, we employ a variety of machining technologies and advanced processes to achieve the highest quality standards in the nuclear industry:

Turning

Our turning machines—also known as turning centers or lathes—remove material from the outside of the workpiece while it “turns” on either a horizontal or vertical axis. Our turning equipment is used to produce Greer Stems and Anti-Extrusion Rings, Shaft Sleeves, Pump Shafts, Flanges, and Heat Exchanger Shells.

Turning Equipment:

- Tri-Tool Beveling Range 7”-42”, O° – 37 1/25” Long, 12”-50” Facing

- Lathe Diameter-20” (Swing 4” Thick), Length-60”, I.D. Clamping -3”, 14” Max, O.D. Clamping-3/16” Min, 14” Max, Accuracy .004- .007 Turning, .001-.003 Drilling & Boring, Tapping up to 5/8” Thread x 3” Long, Steady Rest- 1”-6” (Small), 6”-10” (Large)

- YAMA SEIKI Vertical lathe with 15-inch chuck and FANUC Control

- ROMI M 27 Horizontal lathe with 20-inch chuck, and Fanuc Control Programmed with Fusion 360.

Milling/Drilling

With our milling and drilling machinery, we can cut a variety of precise shapes out of, or drill holes into, stationary workpieces of a variety of sizes, dimensions, and thicknesses. We use this process to produce Greer Stems, Anti-Extrusion Rings, and Tube Sheets.

Milling/Drilling Equipment:

- Hurco VMX 42 with WINMAX conversational control

- Bridgeport Height-16” (Up, Down), Width- 36” (Left, Right), Depth-12” (In and Out), Head Tilt-45° forward and 45° backward, Accuracy .003-.005, and 2”

- Hurco Height-24” (Up, Down), Width- 40” (48” Table)(Left to Right), Depth-24” (In and Out)

- GBC Plate Beveling Machine. (Max cut 1.5” at 45 degrees)

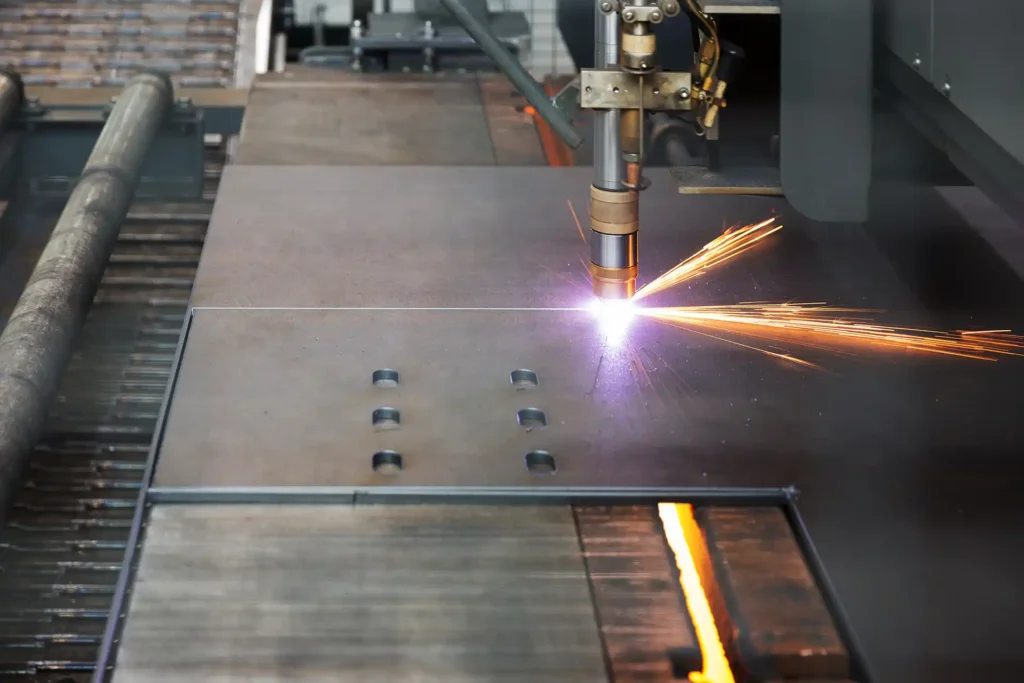

Cutting

We can fabricate a variety of metal components to a wide range of shapes and sizes with our high-tech cutting machinery that includes saws, plasma cutters, and more.

Cutting Equipment:

- Marvel Saw – The largest cut size is 13”H X 13”W

- Marvel Saw – The largest cut size is 22”H X 18”W

- Kalamazoo Saw – The largest cut size is 18”H X 18”W

- Line Burner – Maximum cutting depth of 8”

- Plasma Cutter – Maximum cutting ¾” (stainless steel)

- Burn Table Hypertherm A bed – Has a capacity of 10’x24’, plasma max cutting depth 3” SS & 2” Mild Steel, Gas torch max cutting 6” carbon steel

- Hand Plasma Thermal Dynamics Cut Master 151 Max cutting depth of 1 ½”

- Dake TECHNICS 350CE Cold Saw Capacity of 4 ¾” Round mat. & 6 ¼” x 3 ½” Rectangle and can miter 45° to left and 90° to right

- Sheer/Punch (Geka Hydracrop 55) – Punching 1 ½” x 3/8” or ¾” x ¾”, Shear flat stock bar 12” x 5/8” or 8” x ¾”, Shear 90° angle 4” x 4” x 1 ½”, Shear solid round bar 1 9/16”, Notching 3 ½” x 1 5/8” x 3/8”

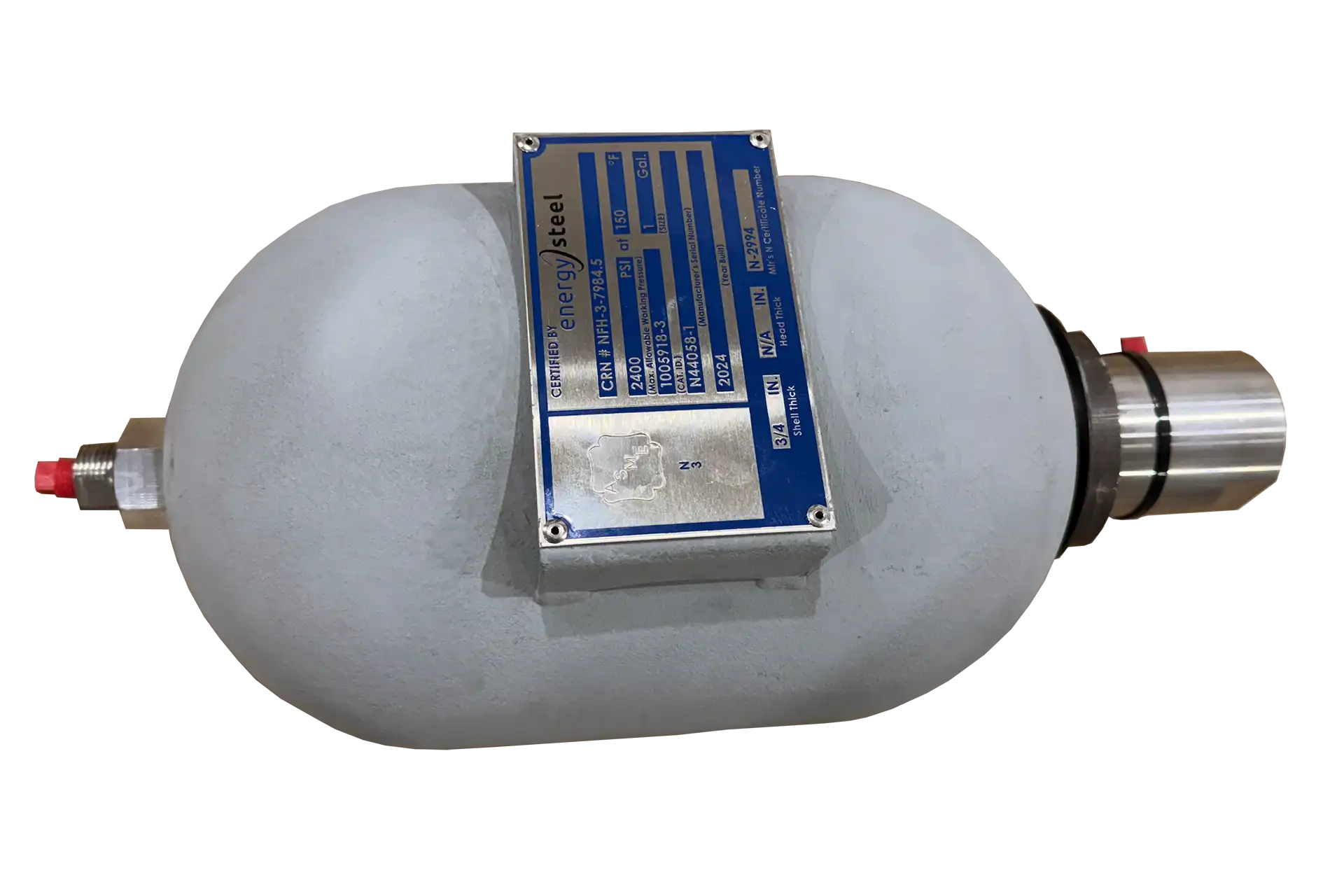

Products We Machine

Want to Learn More About Our Machining Capabilities?

Fill out the form, and one of our product experts will be in touch shortly to answer your questions, provide detailed information, and guide you through the process.